It’s our anniversary! This fall we’re celebrating 85 years of craftsmanship, innovation, style, service, and quality. We picked Labor Day to kick off the party—a day that honors the great tradition of the American worker. Appropriately, we’re celebrating 85 years of jobs well done. We’re so incredibly proud of our workers—from the craftspeople who make our wood pieces to the designers who help our customers create beautiful rooms.

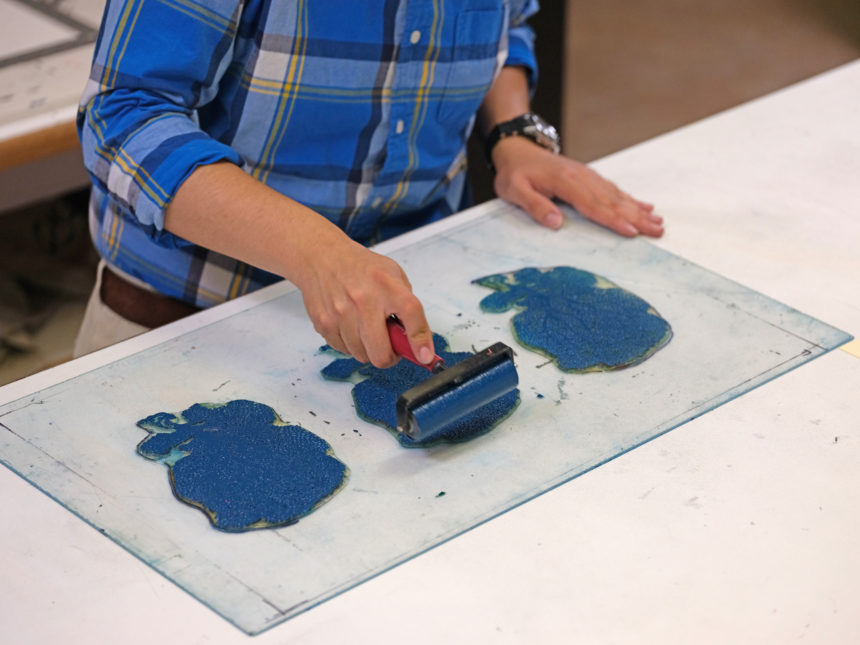

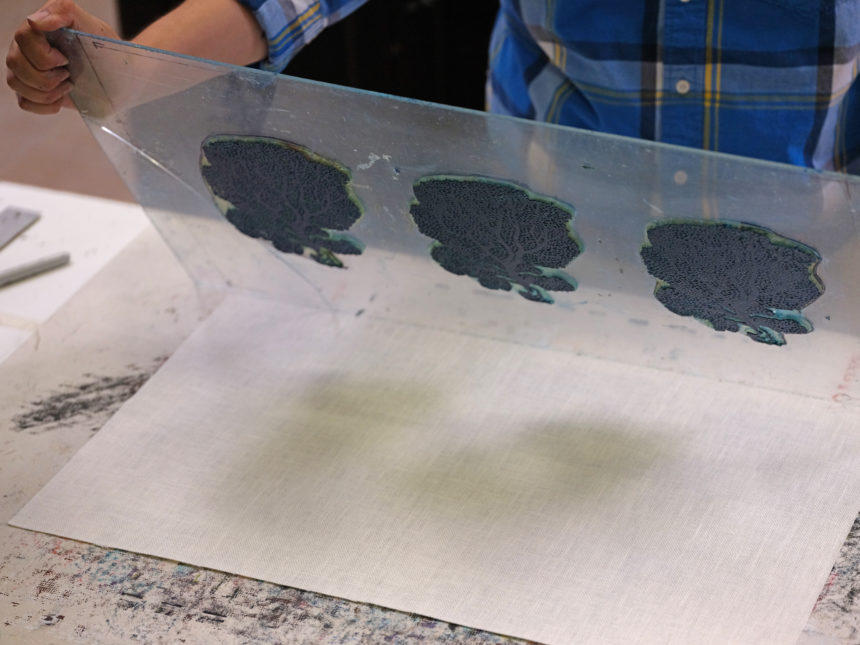

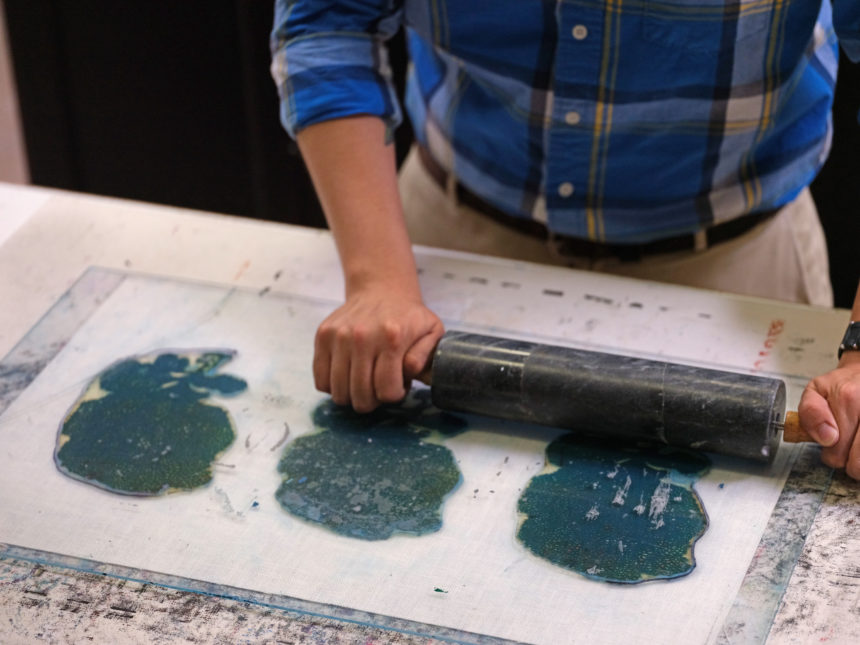

Throughout September we’ll be celebrating our history (look for highlights of our timeline), our favorite anniversary palette (beautiful black and gold), and the creativity of our artisans. We’ll be sharing entertaining “then and now” stories and going behind the scenes inside our photo studio and manufacturing plants.

Don’t worry. We’ll still be sharing our Design Stars’ stories and serving up fresh decorating ideas, but we’ve got some serious celebrating to do this September.

We may be 85, but we can party with the best of them—come along for the ride!

—The Ethan Allen Design Team